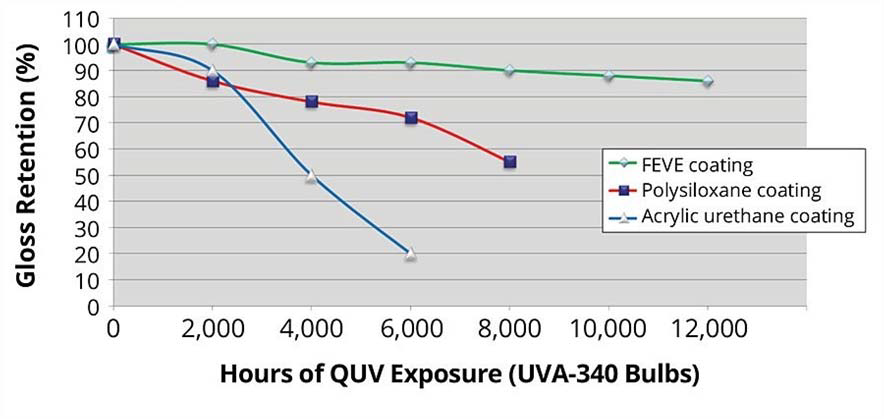

• The FEVE Coating is the type of Fluoropolymer we have.

• The Polysiloxane coatings are a newish coating system with

enhanced UV and chemical resistance compared to more

traditional protective coatings, such as epoxies.

• Acrylic Urethane coatings are an enhanced acrylic

coating system, with urethane, in a 2 pack mix for superior

performance in exterior conditions.

• The results in the graph, with at least 80% gloss level remaining

• FEVE Fluorploymer, 12,000 hrs exposure

• Polysiloxanes: 3000 hrs exposure

• Arcylic Urethanes 2000 hrs exposure

• Meaning FEVE Fluoropolymers are able to withstand

9000 to 10,000 more hours of UV radiation than the

others, in an accelerated environment test.

• As a guide, each 1000 test hours equates to about 1-year of exposure in the Australian climate.

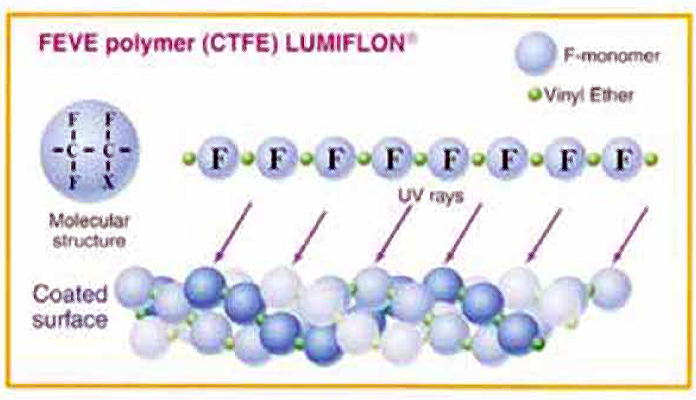

• For paints Ultra Violet (UV) sun rays are the killer!

• Most paints usually degrade quickly and need a

recoat within 6 – 7 years

• A&I Fluoroploymers (FP) are engineered better

to resist this

• The FP long chains of very high strength

molecular bonds cannot be broken by UV attack

• FEVE Fluoropolymers are basically inert and very stable

• Means a very long-lasting & proven coating, ideal for tough situations

Key Benefits of A&I Fluoropolymer Coatings are:

⇢ Highly Durable – proven to last more than 30 and expected up to 60 years in very aggressive environments.

⇢ Protective – shelter the underlying substrate from the ravages of the environment.

⇢ Great Value – very competitive when compared to the best of the existing coatings.

⇢ Very Stable – resists any deterioration.

⇢ The ultimate resistance to the degradation caused by UV light – long term gloss retention.

⇢ Very long-lasting – save expensive, disruptive and unplanned maintenance costs.

Overall the most economic of coatings when compared to all others during their life.